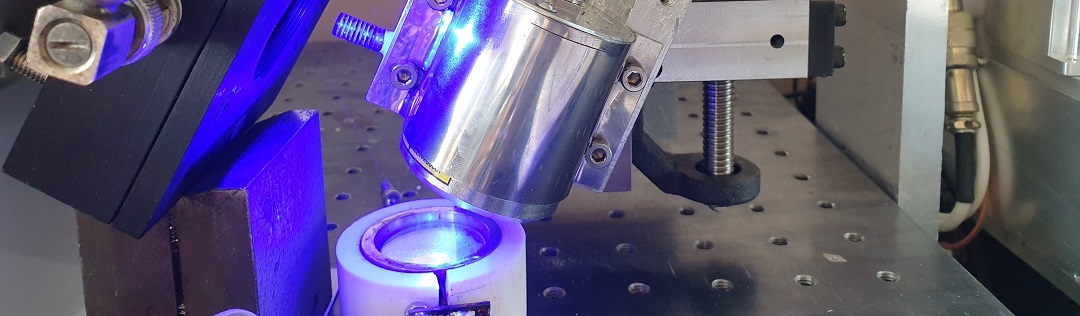

Laser soldering system

Watch our 3 min video presentation form ASSL/LAC, December, 2022, paper JW3B.13

Goals: Design andtive laser soldering system based on commercial CW 450 [nm] diode lasers.

Main goal of the project was a design of a system that allows heating of the soldering point with a specific, predefined temperature profile. For this purpose, first we need to know behavior of reflectivity of the soldering alloy

During the project we measured reflectivity in wide temperature range, including melting point for two different wavelengths, 450 [nm] и 808 [nm], were commercial and cost-effective diode lasers exist. Main work on this point was connected with the setup for reflection measurement and construction of heater with precise temperature control. Common heater was used in the setup for surface properties of liquid metals as well as for precise temperature stabilization of a nonlinear crystals in Laser Mode Locking setups.

After we have some knowledge on reflection behavior of the liquid solder, the next step was a development of laser system that allows heating of the sample wit predesigned temperature profile. For these purposes standard software and hardware control of a commercial diode laser emitting at 450 [nm] were modified in order to generate light pulses with and arbitrary shape.

Additionally, we have developed a theoretical model, based on thermodynamical considerations, that allows us to calculate laser pulse shape required to heat the sample with a specific, predesigned temperature profile.

We first start our experiments wit square laser pulse shape. Corresponding temperature profile (black curve) has a typical behavior. During the laser pulse temperature rise almost linear, and then the sample start to cool by natural convection. Red curve is the theoretically calculated with no losses taken into account. There is only slide deviation between the theory end experiment at higher temperatures and as expected theory predict a bit higher maximum temperature.

If we can neglect losses during heating phase, we can not do it at holding temperature. Measured losses in J/s at different temperatures are shown on the left. If we exclude the region around the phase transition, this dependance is linear. Inserting this data into our theoretical model we ware able to predict generated temperature profile. Figure on the right shows the experimentally measured profile in black with the excellently overlapped theoretical curve in red.

Publications:

1. H. Iliev and N. Gorunski, Laser Soldering Based on CW 450 nm Diode Lasers, ASSL/LAC, December, 2022, paper JW3B.13.

2. H. Iliev, P. Petkov, N. Gorunski, D. Lyutov, Adaptive Laser Soldering Technology Based on Commercial CW 450 nm Diode Lasers, 2021, International Webinar on LASER, OPTICS & PHOTONICS, July 26-27, 2021, Coalesce Research Group.