Surface properties of liquid solders

Funding: This work has been supported by Sofia University science fund under grants №: 80-10-28/22.03.2021 and № 80-10-15/10.05.2022.

Project goals: Design and construction of equipment for characterisation of surface properties of liquid materials with low melting temperature, up to 400 [deg. C]

Results

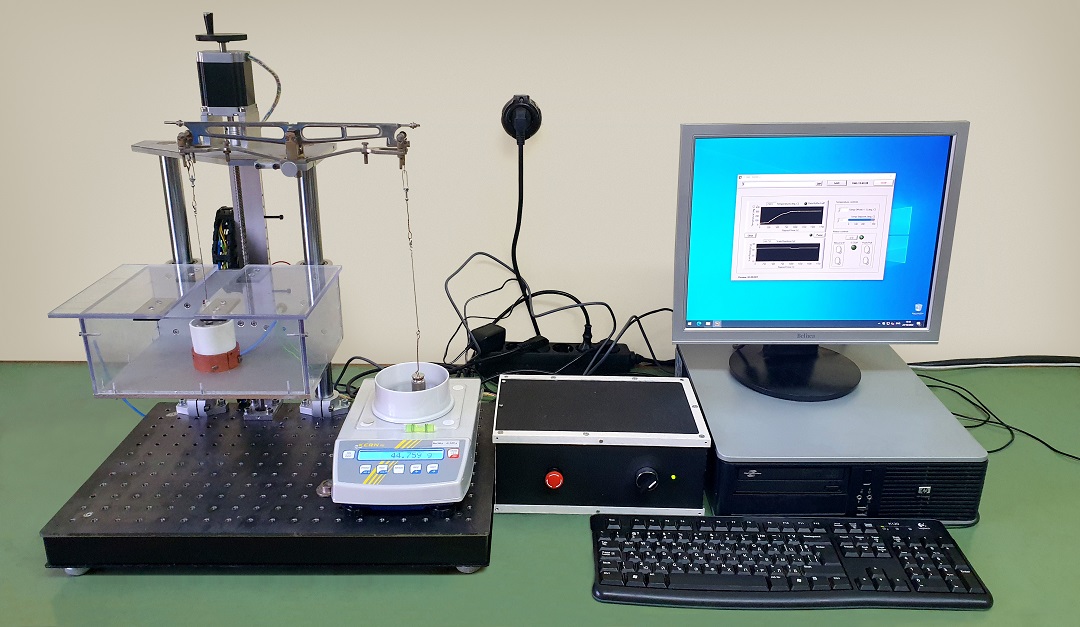

Main result from the project is a fully functional prototype of a system for surface properties characterisation, appropriate for materials with low melting temperature. The described system has following main features:

- wide temperature range - the system allows measurement of the surface tension of the sample in a wide temperature range varying from room temperature up to 500 [deg. C]. With some additional modifications of the heater the specified temperature range, can be increased to higher as well as to lower temperatures. This makes the system appropriate for surface tension characterisation of wide range of materials and alloys.

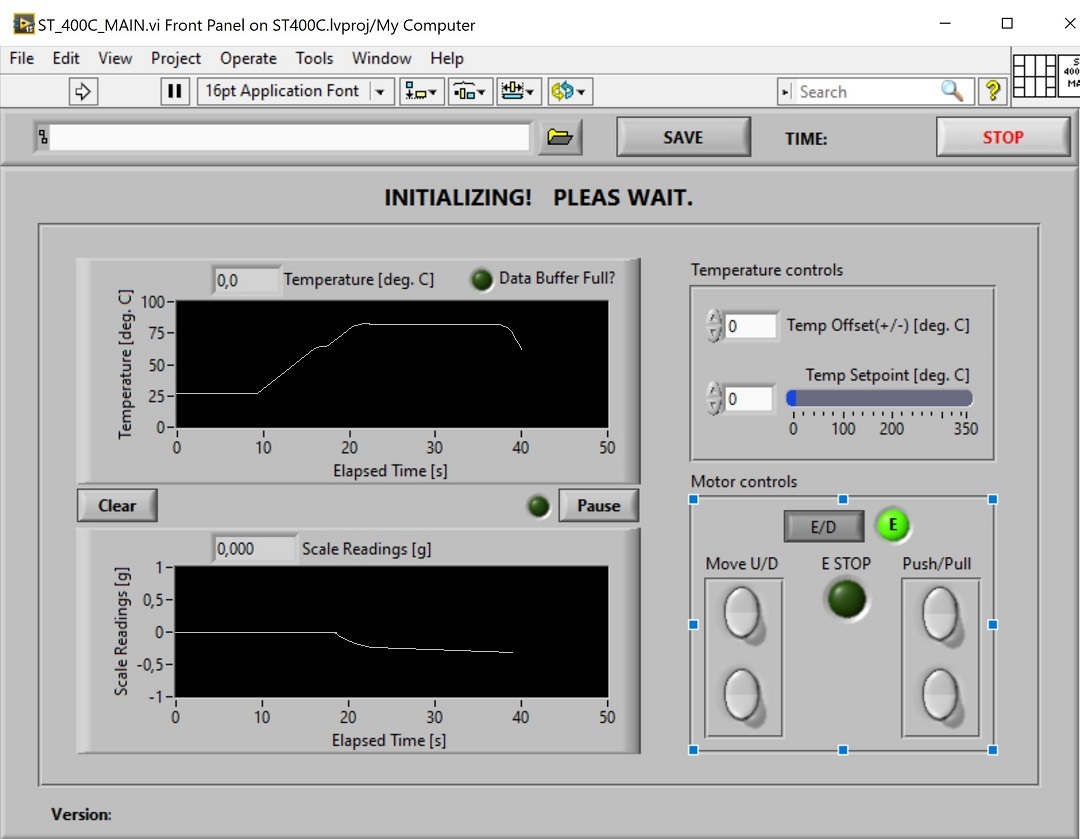

- fully automated - internal PID algorithm ensures precise control over the temperature of the sample. Positioning of the measuring plate and the sample is automated by stepper motor and controller. All features can be controlled bay intuitive user interface based on LabView. It also collects the data for the time, temperature, and surface tension force. Communication protocol with the main controller and simple communication examples based on LabView are also available.

- different atmosphere – the system design allows confinement of the sample in a small volume where user can create different atmosphere, CO2, N2, O2 etc. All materials used for the heater and the camera are chemically stable and allows operation even in chemically active atmospheres, like some fluxes used for soldering.

As a side effect, there are also some additional technical results forma the projects that are relatively universal and can be used in other applications. For example, the main controller is based on standard STM32 microcontroller, communicating over serial port with a standard PC. It is capable to control simultaneously up to 3 stepper motors, with 8 digital inputs, 8 digital outputs, 4 analog inputs and two independent PWM outputs. The heater of the sample and the temperature controller are also useful tolls and can be used for different educational and scientific purposes.

Whole user interface (see fig below) for communication with the main controller, control of the different modules, collecting of the data and their extraction was developed by the team and it is based on LabView. Picture of the user interface can be seen below.

Whole system, mechanical design, software, and the hardware is based on standard components, as well as components developed by the team especially for the goals of this project. Fully opreational prototype can be seen on the picture below. With some minor modifications connected with engineering of the current prototype, the system can become appropriate event for industrial applications. However this is out of the scope of the current scientific project and has to be done in partnership with the industry as a technology transfer.

More information about separated modules and their features can be found int the section “Technology transfer “.

Of pure scientific point of view, the project also achieves good results.

We first start with characterization of alloys where non-surface-active film formation was observed. We use this to validate and verify the constructed prototype. At this stage we studied two alloys in the temperature range from the melting point up to 325 [deg. C]. Both alloys are standard Tin-Led alloy used in the electronic industry. The most popular eutectic alloy 60/40 with a melting temperature around 185 [deg. C], and non-eutectic 40/60 alloy with a melting temperature up to 210 [deg. C]. In both cases liquid metal does not show formation of any surface active films leading to substantial variation of the surface tension with the time.

A comparison of the results achieved with the constructed prototype, and these found in the literature, shows good correlation. It was also developed a theoretical model for estimation of the surface tension in nonequilibrium state and the results of this model were compered with the experimental data. Additionally, it was found that during cooling of the sample, an intensive process of formation of small scattering crystals occurs at the interface of the sample with the surrounding air. At subsequent melting of the sample this crystals float on the top of the sample and needs to be cleaned up before the next measurement.

We collect all these fine particles and studied them with an X-Ray spectrometer, to determine their chemical composition. Used spectrometer was calibrated only for pure materials, not for oxides and in the future work we plane to calibrate this toll using known chemically synthesized oxides.

The results from this experiments were published in a full text publication (1).

Next logical step in the project was to study surface properties of alloys where surface active film was formed as a result of the contact of the liquid metal with the air. Pure tin is a god example of such material. The constructed prototype also allows us to study the evolution of the process and its kinetic.

Since 2006 RoH standard enforce use of Led free solder alloy. Typical example is Sn100 (pure Tin) and alloys with small amount (<1%) of Copper (Cu), Silver (Au) etc. Some of these alloys are also eutectic but in any case, all of them have significantly higher melting temperature around 220 [deg. C]. Moreover, they show strong kinetic when liquid metal is exposed to air. The oxidation process starts immediately, forming a thin surface active layer that is changing with the time. Major investigations in this experiments were conducted with formation and evolution of this surface active layer and haw it change surface tension of the sample. In the process of measurements we found out that there is slight deviation of the measured melting temperature, and the one found in the literature. Check of the chemical composition of the sample shows us tat our sample contain around 2 % of Pb, leading to slightly lower melting temperature. All of the following experiments were performed with pure certified tin with purity of about 99.9 %.

The results of this measurements were reported at one international forum in (2).

All experimental results were reporter at one international forum. There is also one full text publication in. We are also planning one more full text publication in an international journal.

- List of full text publications.

- Plamen V. Petkov, Dimitar Lyutov, Nikol Borisova, Boyan Todorov and Hristo Iliev, “Experimental Investigation of Liquid Tin Surface Property Safety Features for Potential Application as a Coolant in Direct Contact Liquid Metal Fast Reactors”, International Conference on Topical Issues in Nuclear Installation Safety, 2022, Vienna, Austria, paper #75

- Plamen V. Petkov, Dimitar Lyutov, Hristo Iliev, Investigation of solders surface tension in temperature range from melting point up to 673К Machines. Technologies. Materials. Vol. 15 (2021), Issue 2, pg(s) 69-72.

- International scientific forums

- Dimitar Lyutov, Plamen V. Petkov, Nasko Goriunski, Boyan Todorov and Hristo Iliev, Study of surface properties of molten Tin, exposed to air up to 600 K, 3-rd International Webinar on “Material Science & Nanotechnology”, 16/09-17/09 2021